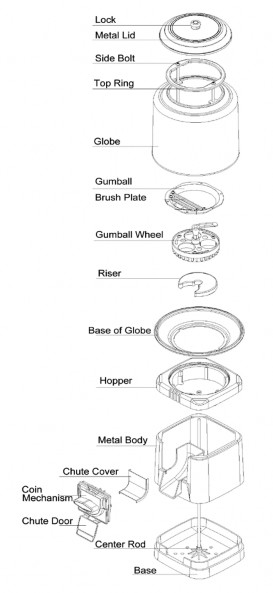

Rhino All Metal Classic RH501M MANUAL

Initial set-up

Click here to see the Rhino Classic Vending Machine Line

Click here to see the full Rhino Vending Machine Line

-

To change wheels or wheel settings:

-

Unlock and open globe lid by unscrewing lock

-

Remove two side blots holding globe to hopper; (Fig.1)

-

Remove candy brush plate from the hopper;

-

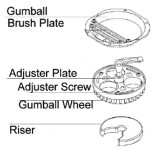

Lift up adjuster plate and move to the desired wheel setting notch (fig.2). Notch #1 (the notch to the far left) is for the smallest vends and notch #6 is for the largest vends. The adjuster plate can be completely removed if desired for vending large product such as peanut M&M.

Figure 1

-

for gumballs/capsules(or bouncy balls), you will need to use gumball wheel and brush plate. The gumball wheel is installed by first installing the riser (Fig.3), The opening of the riser must face the front of the vendor. Next, install gumball wheel so that one of the vending holes is positioned over the opening in the riser, install the gumball brush plate. Loosen the one (1) adjustment screw on top of the gumball wheel located next to each ball cavity. Turn the adjustment gumball wheel to adjust the opening according to the product being vended. The springs on the gumball brush plate must be towards the coin mechanism or the front of the vendor.

When your portion vends at the desired setting, continue filling the vendor with product, replace the lid and install lock. NOTE: DO NOT OVERTIGHTEN THE LOCK AS ONLY A SNUG FIT IS NECESSARY.

Figure 2 Pan Candy Wheel

Figure 3 Gumball Wheel

CandyMachines.com

-

-

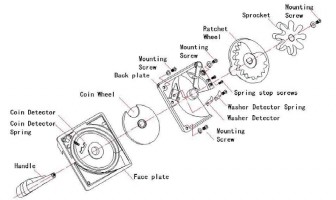

Coin Mechanism

The coin mechanism (Fig.4) can be removed by removing the globe lid and lifting off the globe assembly. Once the globe assembly is removed, the coin mechanism can now be lifted upwards and removed.

-

To dismantle coin mechanism

-

-

remove center screw

-

remove sprocket

-

remove three(3) mounting screws

-

pull back plate away from face plate

-

remove jammed coin

-

replace parts in step A-A in reverse order

Figure 4 coin mechanism exploded view illustration for adjustment and maintenance only. Coin mechanism parts not sold separately.

-

-

Unlock and open globe lid by unscrewing lock. Note: globe lid is only resting on the globe.

-

Lift globe assembly and set a side on a secure surface.

-

Retrieve coin from base

-

Replace globe assembly

-

Replace and tighten lock, Note: do not over tighten the lock as only a snug fit is necessary.

-

-

OF 4

Rhino Monster Cast Iron Stand

The Rhino Monster Cast Iron Stand itself consists of three (3) main parts. The Base threaded Pipe and threaded Flange.

-

-

Place the threaded pipe into the threaded opening on the pedestal base and tighten.

-

Place the threaded flange onto threaded pipe, flat side up.

-

Secure the pedestal base and tighten the threaded flange by turning clockwise.

-

Unscrew lock, remove metal lid, lift top assembly off bottom assembly, and remove coin mechanism, bottom base is now exposed for mounting.

-

Align holes in vendor’s base to the large holes in the threaded flange(Fig.7)Note:

The front of the base has a notch for the product chute.

-

Insert two (2) bolts from threaded flange through base.

-

Apply washers and nuts. Tighten. Do NOT OVER THGHTEN.

-

-

Complete steps A-A as shown in single mount.

-

Place large double bracket on top, and align large holes in threaded flange holes in large double bracket. (Fig.7)

-

Insert blots as shown. (Fig.7)

-

Disassemble both vendors to free bases. (See: coin Retrieval)

-

Align front and rear most holes in base to the outer most holes in the large double bracket. (Fig.7) Note: The front of the base has a notch for the product chute.

-

Insert two (2) bolts (per vendor) down from the large double bracket.

-

Apply washers and nuts tighten. Do not over tighten- over tightening can crack the base and void warranty.

-

Reassemble vendors.

-

-

OF 4